Manage Machine-Intensive Operations with Real-Time Oversight

An industry model for an open-pit mine producing 80,000 tons of ore per day estimates the cost of the required machinery to be in excess of $47.5M.(1) These high-value assets must be carefully managed to ensure uptime is always optimised, which in turn will maximise production.

Optimise Maintenance Costs with Condition-Based Monitoring

While most mining operators use a time-based preventive maintenance model, studies have shown that the forced maintenance timeline often leads to wasted costs, and in some cases even equipment damage. Rajant Kinetic Mesh® networks allow mines to move to a condition-based monitoring paradigm by bringing them the data needed to proactively monitor equipment health and deploy maintenance only when issues present themselves.

Real-World Functionality for Real ROI Results

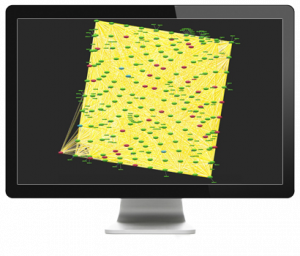

Rajant Kinetic Mesh® networks have been implemented in some of the largest mining operations around the world to reliably cover people and assets across all remote operations. Below is a screen shot of an actual Rajant mining network spanning 145 square miles with over 200 BreadCrumb nodes. Rajant’s infrastructure can even span beyond the mine itself, creating a seamless pit-to-port network for transformative communications efficiency.

Featured Video

Watch the video to see Bob Schena, CEO and Co-Founder of Rajant, discuss how Kinetic Mesh® networks enable wireless connectivity for mining, powering continuous condition monitoring of vehicles and equipment across these rugged operations.