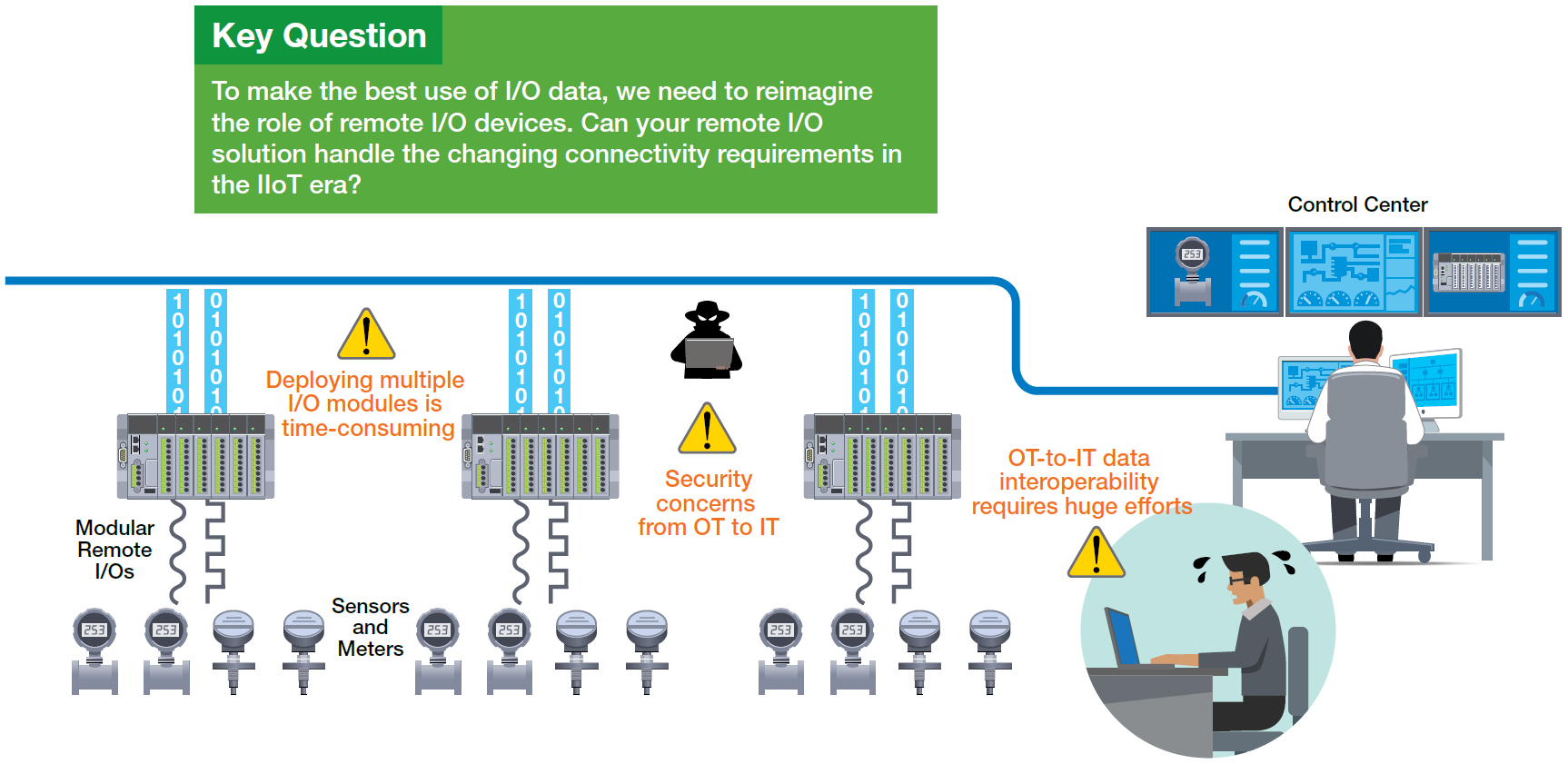

You cannot draw actionable insights for Industrial Internet of Things (IIoT) applications without data. Remote I/O devices that are used to send and receive input and output signals to and from your sensors, controllers, and other equipment in the field may not resemble the “smart” automated robots immediately associated with the IIoT, but without these humble I/O workhorses, you wouldn’t have any of the remote I/O data you need.

Remote I/O devices are usually deployed at field sites to enable data access and environmental monitoring from a distant control center. I/O data acquisition not only ensures smooth daily operation for your field application, but also provides potential insights that can be used to optimise productivity.

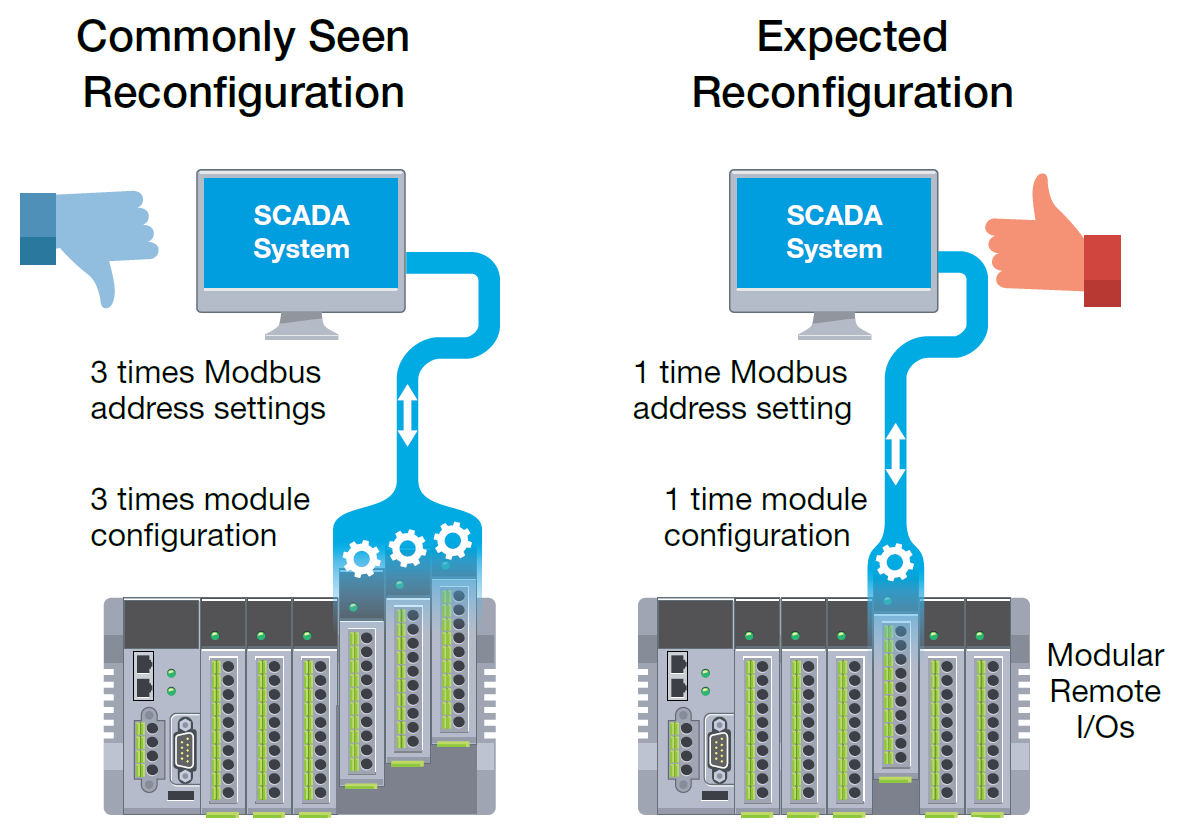

However, the rising complexity of IIoT systems and applications is pushing traditional data acquisition to its limits. Modular remote I/O devices offer clear advantages by allowing you to customise the I/O modules on the remote I/O device itself. In other words, you are free to pick and choose the specific types of I/O modules you want to use, when to use the modules that give you flexible expansion, and how to use the modules based on your choice of communication means. Although modular I/O devices may not be the newest solution on the market today, the flexibility they enable continues to raise our expectations for how to acquire remote data from every node.

Key Criteria for Choosing a Modular Remote I/O

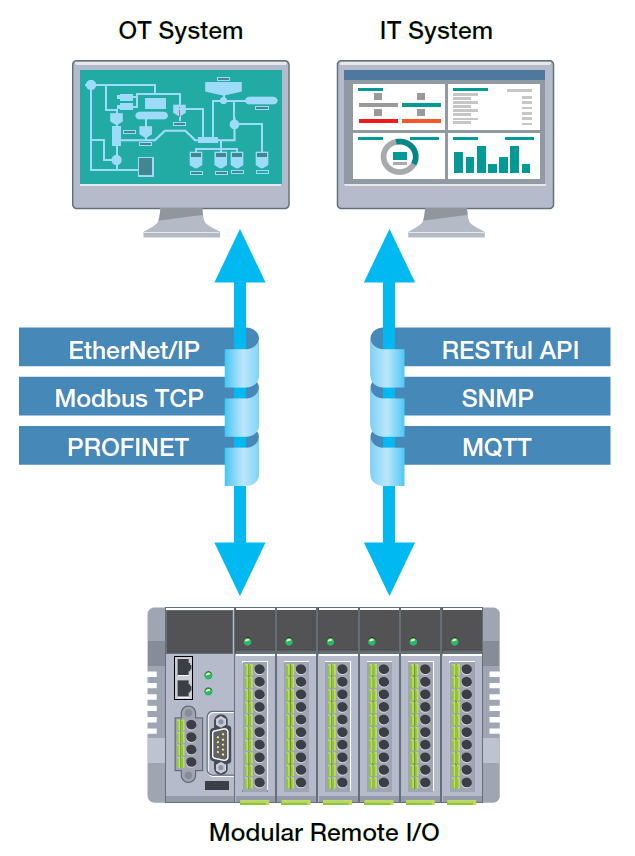

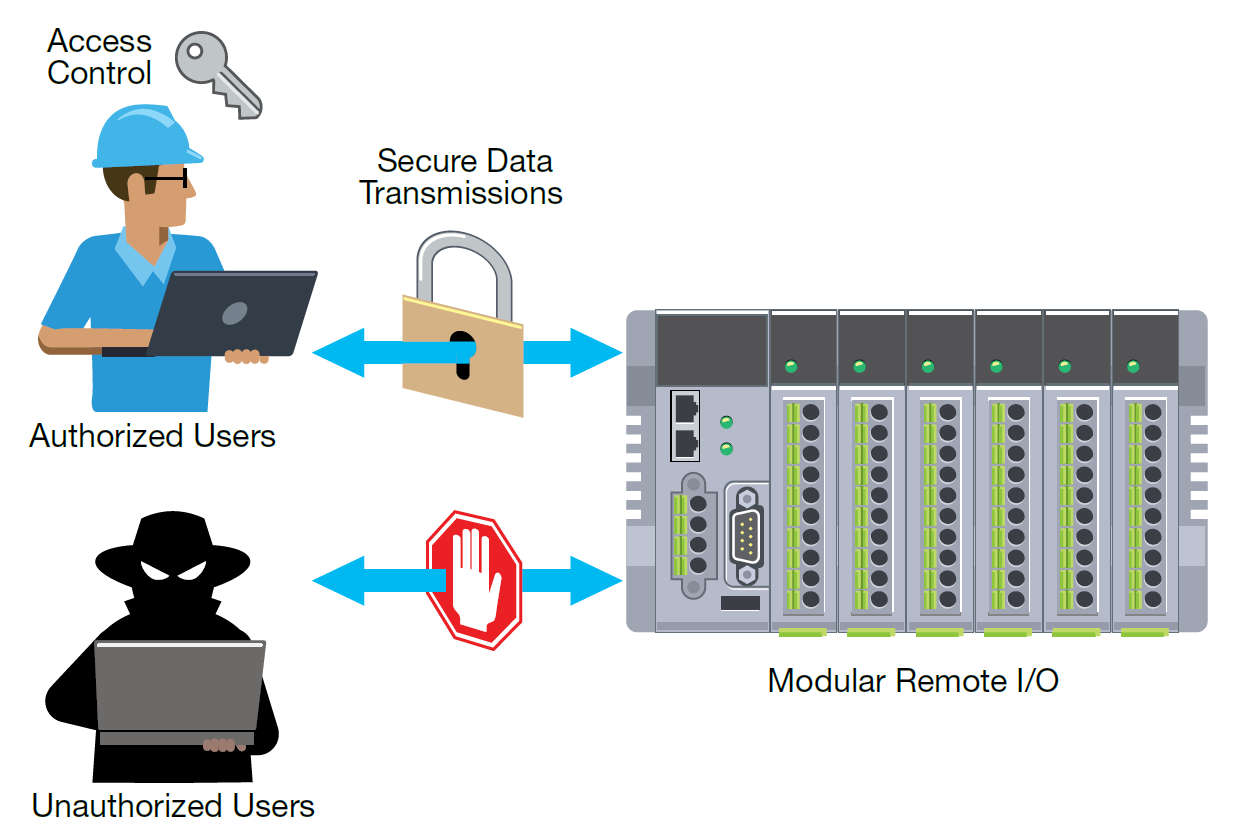

It’s crucial to choose a modular remote I/O solution that helps you make the best use of your collected data from installation to operation and maintenance. At the same time, you also need to ensure that both your OT and IT systems can use the data you acquire. Last but not least, your remote I/O solution should include or support cybersecurity features to protect the data you painstakingly collected. In this section, we share these key considerations in detail.