Five Important Questions to Consider Before Powering Industrial Systems With Power over Ethernet (PoE)

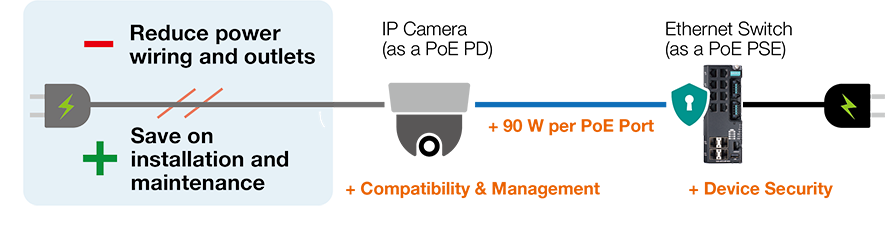

Are you experiencing challenges connecting devices to your industrial systems or transferring data while simultaneously providing large amounts of power to powered devices (PD), such as IP cameras or wireless access points? Power over Ethernet (PoE) is a power supply mechanism that leverages cables to transmit power via power sourcing equipment (PSE).

The benefits of PoE include cost and time savings as well as higher flexibility. For example, you can reduce time and costs for electrical installations, as you do not need to install a new power outlet at every endpoint.

Furthermore, using a PSE eliminates the need to be tethered to fixed electrical sockets. You can install PDs where they are required and connect them easily to PSEs, such as a PoE switch. If changes or expansions are necessary in the future, it is much easier to reposition the PSE as opposed to being forced to use fixed electrical sockets.

However, as there is growing market demand for higher resolution IP cameras and wireless access points that connect to more devices, current mainstream 15 or 30 Watt PoE is no longer sufficient. Furthermore, ensuring that PSE and PDs are compatible with each other can be time consuming and it is not a task that industrial engineers enjoy undertaking.

In this article, we want to look at the answers to some important questions we typically encounter focused around the system lifecycle of industrial systems. By the end of the article, you will have gained a better understanding of how to deploy industrial systems that utilize PoE solutions.

Before Purchase – Evaluation

Question 1: Which PoE standard can support my power-hungry PDs such as IP cameras?

Have you ever encountered the situation where you bought an IP camera and found it challenging to figure out which PoE switch can support the IP camera? It is essential that you give proper consideration to the compatibility between PSEs (e.g. PoE switches) and PDs (e.g. IP cameras) when developing your industrial systems to avoid issues in the future.

Soon after the IEEE 802.3af PoE standard was introduced in 2003, industrial engineers recognized its benefits and since then the amount of PoE switches deployed in the field has been steadily increasing. However, as the devices continue to evolve and become more complex with new features such as object detection and light scanning, they require more power. Manufacturers have responded to this trend by creating proprietary protocols to support higher power output. However, this can sometimes have the unintended effect of causing compatibly issues between PDs and PSEs. When planning an entire system, it is essential to consider these potential issues when selecting networking devices. Interoperability can be tested via various tools that can detect voltages and monitor power capacity. It is highly recommended to choose PDs and PSEs that follow the IEEE 802.3 at/af/bt standard or utilize a tool or software, such as Sifos, to test the device and ensure compatibility before deploying the device to the field.

Question 2: What is the best way to determine if I have sufficient bandwidth?

Have you ever encountered the scenario where the network is up and running but because data packets are delayed, the footage from the IP camera does not transmit properly? For many industrial deployments, it is a requirement to transmit real-time high-quality snapshots or video streams to the control center, which can often cause a surge in the amount of bandwidth required.

Therefore, it is essential to check whether PoE switches have sufficient bandwidth available to reliably supply high-quality video taken on 4K or UHD cameras without degradation of quality or video loss. Although, full-Gigabit-port PoE switches can reliably fulfil this requirement, they can be a prohibitively expensive option. An ideal solution is to utilize PoE switches that have Gigabit, or even 2.5 GbE port combinations, as this will enhance the flexibility of your network without forcing you to purchase the most expensive option.

After Purchase – Installation

Question 3: How can I reliably set up my PoE devices on networks without knowing the power consumption requirements for each PD?

Have you ever encountered a situation where you had to check the PoE power consumption of your powered devices, such as IP cameras, and then had to configure your PoE switches to match that standard? As this task can be a bit cumbersome, we should consider alternative solutions to simplify this task.

A frequently encountered scenario is when someone wants to use a PoE switch that supports up to IEEE 802.3bt 90 W output, but the powered devices, such as wireless APs and IP cameras, utilize power from 15 W to 90 W. With recent advances in technology, there are now solutions available that allow you to avoid this issue. One example is PoE switches that can automatically detect the power consumption of powered devices, which removes the requirement to input the PD’s parameters into the web GUI. It has been acknowledged throughout the industry that the feature that automatically detects power consumption significantly simplifies configuration and deployment.

After Purchase – Maintenance

Question 4: What is the best method for me to determine if there is an issue with my PD that has been deployed remotely?

Have you ever had a customer inform you that one of their IP cameras is not functioning correctly and they need the problem solved immediately? As is often the case, the IP camera could be located hundreds of miles away, which can make asset owners reluctant to deploy engineers to the field site without a high level of certainty that they will be able to fix the problem. What is often required in this situation is more information about the issue.

Industrial applications are usually located in remote, harsh environments. Ideally, PoE switches should be able to perform failure checks and automatically reboot PDs remotely. This will provide the owner with more information about what is happening at the field site so that if it is necessary to dispatch personnel, they arrive with the correct equipment to rectify the situation quickly. One of the most effective ways of achieving this is to set up emails, relay, or trap notifications, to provide information about the status of the PD. In addition, management software makes it easier for you to determine what issues your devices might be experiencing at remote sites. It is therefore advised to leverage any available software management features to gain insights about why the device failed, which will assist you to make more informed decisions before dispatching personnel to the site.

Question 5: What steps can I take to enhance the security of my networking devices?

Did you ever believe that because your IP surveillance systems are in a closed loop and are air-gapped that they are protected from cybersecurity threats? Unfortunately, this is not correct. In fact, you may have read news reports about companies that believed their systems were secure, but their networks were compromised and their video footage was leaked.

Building a robust and reliable network needs industrial network security. In modern industrial environments, there are several different options available for you to achieve this. A recommended approach is to use secure-by-design building blocks that can help establish a secure network infrastructure. Make sure the PoE switches you select are equipped with security features such as HTTPS/SSL, SSH, RADIUS, and TACACS+, which will significantly enhance your industrial network security. Furthermore, it is highly recommended to ensure the vendor you work with has a proper vulnerability management process. When vulnerabilities are reported, there must be appropriate mitigations and communication to ensure your systems can be secure throughout the duration of their deployment.

How an IP Surveillance Innovator Enhances Its Offerings

“The most common challenges we hear from our customers include: a lack of Ethernet port connectivity from a PoE++ injector for other networking devices, no Layer 2 network management functionality for data management, no visibility of the remote PoE++ camera’s performance, and no tools available that can be used for advanced diagnostics. Oftentimes, our customers have to dispatch engineers to perform troubleshooting at the remote site, or physically reset the camera.” Said Lester Miyasaki, Director of Sales at Wireless Technology, Inc. (WTI), a global Video Surveillance Systems innovator. “We were very impressed with Moxa’s EDS-G4012-8P-4QGS-LVA-T, which is a 12-port Layer 2 managed switch with PoE++ support. First, its auto detection function reports our PoE++ camera type and class to the switch’s Web GUI after it is connected to our camera. Second, the intuitive and easy-to-use Web GUI allows us to manage the PoE++ settings, including power budget and consumption and we can even export the data to conduct further analysis if necessary. Plus, there is also a very helpful feature, PoE++ port power recycle, which assists our customers enhance their productivity by reducing the frequency they need to dispatch personnel to remote sites.”

Conclusion

As industries are constantly changing and customers demand more from their networks, a verified and record-proven solution that can help you meet customer’s demands, will always be a suitable option. Moxa’s EDS-4008, EDS-4012, and EDS-G4012 Ethernet switches have models that feature up to 8 IEEE 802.3bt PoE ports with up to 90 W output per port. In terms of compatibility, Moxa’s EDS-4000/G4000 Series PoE switches passed the Sifos PoE test, which ensures every PSE port meets IEEE 802.3at, IEEE 802.3bt standards, and industry standard requirements for safety and interoperability. Our comprehensive product portfolio with a variety of port combinations including fast Ethernet, Gigabit, and 2.5GbE help you flexibly deploy industrial networks. Last but not least, the EDS-4000/G4000 Series has auto PoE detection and failure check functions to help you quickly set up and maintain your system.