Get Full Visibility for Your Industrial Network with MXview Network Management

Why Network Management is Important?

The primary goal for control engineers, is to ensure that they have system availability, but they often do this without focusing on the network status. This is becoming problematic because even though the Industrial Internet of Things is helping to connect more and more devices, it is unfortunately increasing network complexity and introducing new security risks. Without network visibility, it is very difficult to identify the root cause of problems. Control engineers often have to revert to trial and error to get the system back to normal, which is time consuming and troublesome.

What if control engineers had clear visibility of the network status and could quickly identify the root cause of network downtime?

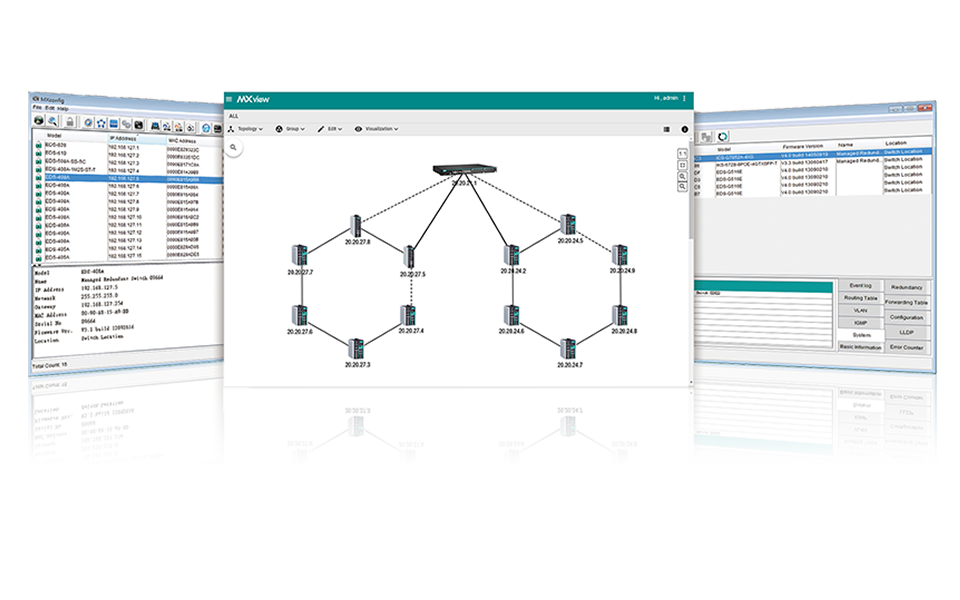

Moxa’s industrial network management software offers visibility of operational technology (OT) that allows network operators to make more informed decisions throughout network deployment, maintenance, and diagnostics. Read on to learn more or download the free trial version to experience MXstudio for yourself.

Explore New Features

Visualise Your Industrial Networks

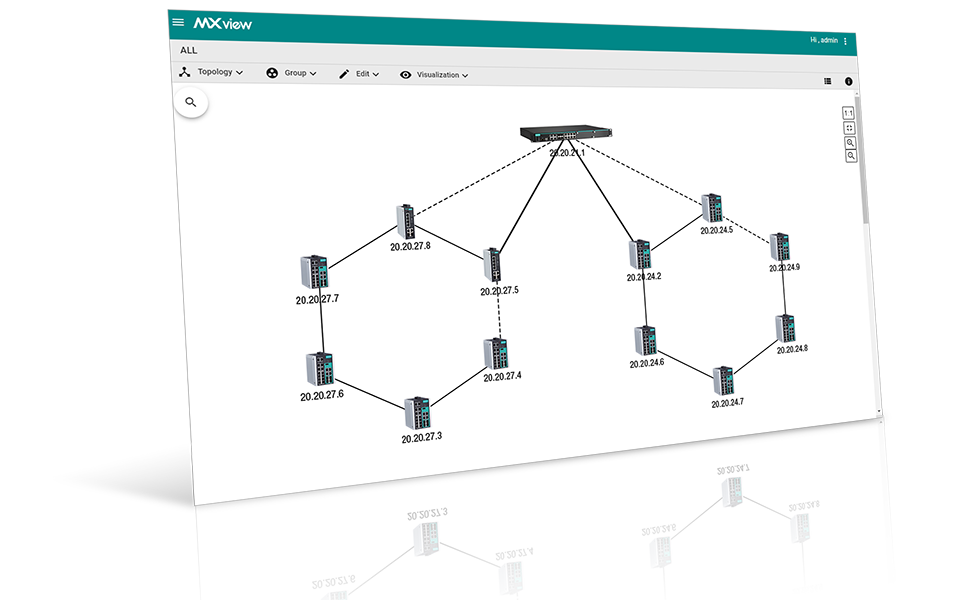

Make the Invisible Visible

Set Up Notifications to Keep Informed About Network Status

Take a Look Inside

Moxa’s Network Management Software Can Help You

Maximise System Uptime

MXview network management software provides real-time alerts when an event takes place on the network and NSnap takes a snapshot to help operators quickly identify the root cause of issues that occurred on the network.

Visualise Network Status

MXview’s new interface helps users easily integrate network management software into their existing systems such as SCADA via OPC DA tags or RESTful APIs.

Manage Device Security

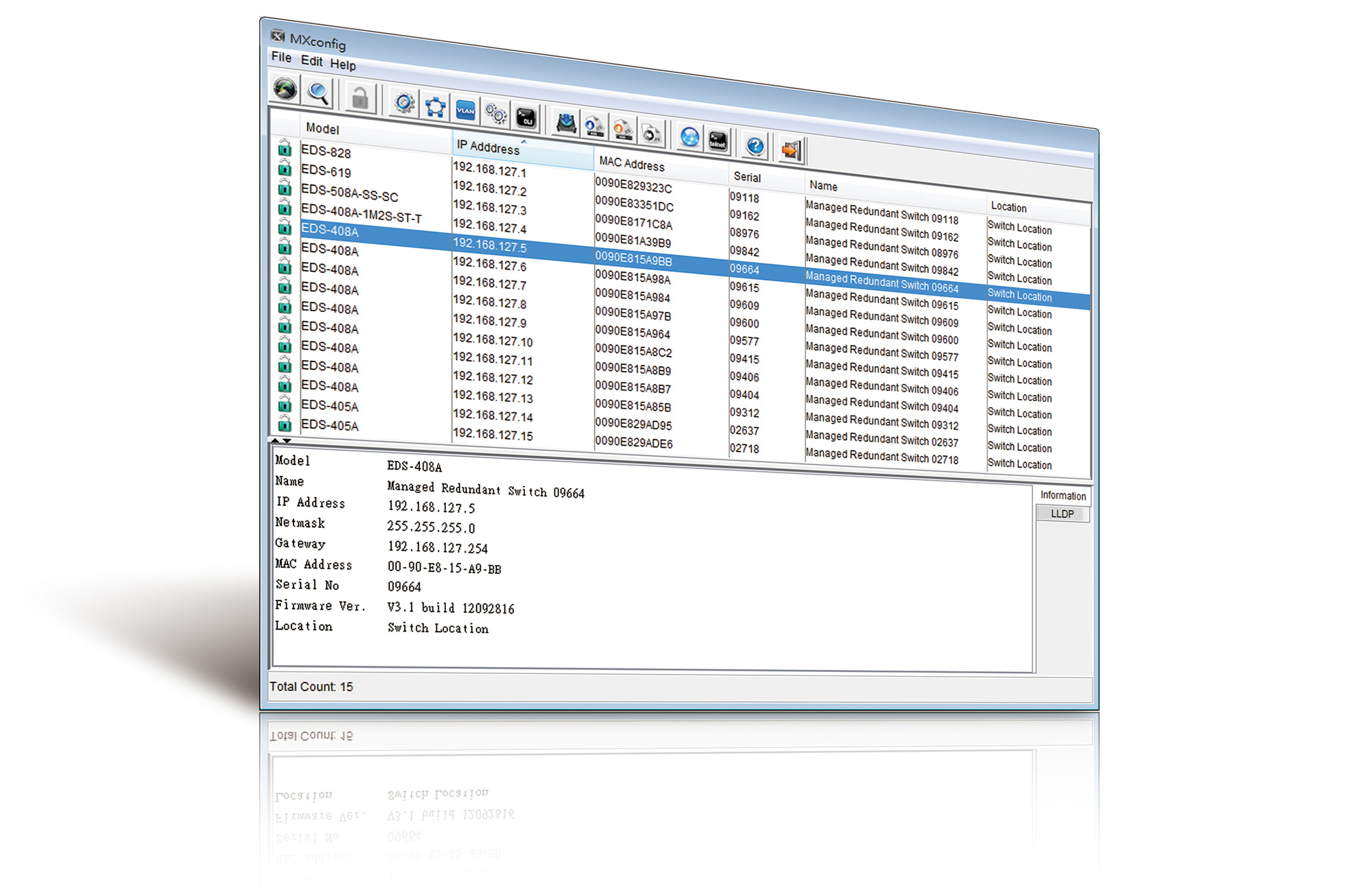

MXview and MXconfig provide visibility and control to enhance device security. Users can view the security status of devices at a glance and quickly enhance the security of their devices.

Understand Why Our Customers Chose MXstudio

Integrating Industrial Networks and Enterprise Networks

A communication device manufacturer wanted to integrate their industrial networks and enterprise networks to increase operational efficiency. To achieve this goal, IT engineers needed to manage both enterprise and manufacturing networks at the same time. The customer chose MXview as it provides RESTful API, which allowed the IT engineers to monitor the network from a single monitor. In addition, by deploying industrial-grade devices with fast recovery times, Moxa helped the customer ensure the reliability of their industrial networks.

Increase Network Device Security With Just a Few Clicks

A water and waste system spanned the majority of a European city and was monitorable from an industrial network. The local government wanted to increase the network security in order to keep the infrastructure secure. As the plant manager was not an expert on network security, it was a challenge to ensure that the network security was sufficient in a short period of time. MXview’s Security View was the ideal solution because it offered a way for the plant manager to visualize the network security status. Equipped with network visibility, the plant manager could direct resources to the parts of the network that needed additional security features. In addition, MXconfig Security Wizard helped the plant manager to identify the critical security parameters. This information was passed to the control engineers who were able to quickly ensure that the device configurations met the industry standards.

Real-time Network Visibility of a Rail Network

A high-speed railway operator built a fiber Ethernet backbone for data transmission between its Operation Management Center and multiple railway stations to ensure high network availability. In order to manage their large-scale networks effectively, the customer chose Moxa’s industrial network management software to help their automation engineers view detailed device information quickly. Furthermore, the software allowed them to quickly identify a specific device among the racks of devices, which shortened the amount of time required to perform maintenance as well as minimized downtime.